Woodworking Shops Simplify Orders With Smart Tools

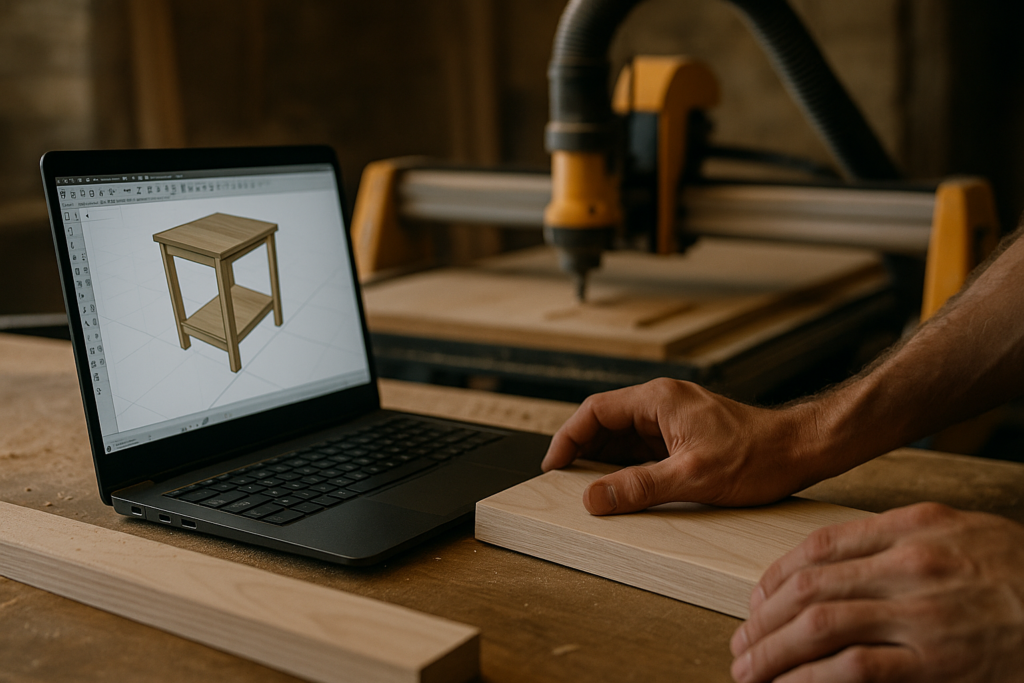

Smart tools have begun to transform the landscape of woodworking, providing artisans and manufacturers with innovative solutions that enhance both creativity and productivity. With the introduction of advanced woodworking business software in the UK, shop owners can now manage their operations more effectively. These tools allow for seamless integration of design and manufacturing processes, enabling woodworkers to create intricate designs with precision. CAD software, for instance, has become a fundamental asset, allowing users to visualize projects in a digital format before any physical work begins. Furthermore, automated cutting machines have minimized human error, ensuring that every piece is cut with accuracy and efficiency. This technological advancement not only streamlines the workflow but also opens the door for more complex designs that were previously challenging to achieve. The collaboration between craftsmanship and technology is reshaping the way woodworkers approach their projects, making it easier to meet customer demands while maintaining high-quality standards.

New in this topic: Top 10 Trends in UK Construction Software for 2025.

Streamlining Order Management

With the rise of woodworking business software in the UK, order management has been significantly simplified for woodworking shops. Traditional methods of managing orders often involved cumbersome processes, leading to delays and inefficiencies. However, by utilizing modern software solutions, shop owners can track orders in real-time, ensuring that every aspect of the ordering process is transparent and easily accessible. These tools allow for the automation of order entry, inventory management, and invoicing, reducing the likelihood of human error and enabling faster turnaround times for customers. Additionally, features such as customer relationship management (CRM) integrated within the software provide valuable insights into customer preferences and purchasing histories, empowering shop owners to tailor their offerings to meet specific client needs. This streamlined approach not only enhances customer satisfaction but also improves communication among team members, as everyone can access up-to-date information about order statuses and inventory levels. As a result, woodworking shops can operate more fluidly, managing a higher volume of orders without compromising on quality or service.

Enhancing Efficiency and Productivity

Efficiency and productivity in woodworking shops have been drastically elevated through the implementation of smart tools and innovative technologies. By embracing woodworking business software in the UK, shops can optimize their workflow, ensuring that every process is not only seamless but also productive. Automated systems facilitate routine tasks such as cutting, joining, and finishing, which allows skilled craftsmen to dedicate their time to more intricate and creative aspects of woodworking. For instance, laser cutting machines and CNC routers can execute complex cuts with utmost precision, drastically reducing the time required for manual processing. This technological shift enables woodworkers to increase their output without sacrificing craftsmanship quality. Furthermore, real-time performance analytics provided by advanced software solutions empower shop owners to monitor aspects such as material usage, labor hours, and production rates. By analyzing this data, they can make informed decisions to streamline operations, reduce waste, and optimize resources. Continuous improvements in workflow also mean that woodworking shops can now accommodate larger orders or more customized requests without the fear of compromising deadlines or quality. The integration of smart tools not only enhances productivity but also cultivates an environment where creativity thrives, allowing woodworkers to push the boundaries of their craft.

The Impact of Technology on Craftsmanship

The integration of technology into woodworking is having profound implications on craftsmanship, challenging traditional methods while simultaneously preserving the artistry that defines the trade. As woodworking business software in the UK becomes more prevalent, craftsmen are utilizing these advanced tools to refine their techniques and elevate their work to new heights. This sophisticated software provides woodworkers with valuable design capabilities, enabling them to experiment with new styles and materials that would have been impractical in a purely manual setting. With intuitive interfaces, artisans can manipulate 3D models, simulate finishes, and visualize their designs with startling realism. This technological assistance empowers craftsmen to make informed choices about their projects before they even touch the wood, reducing material waste and enhancing the overall quality of their work.

Moreover, the precision offered by smart tools does not undermine the artisan aspect of woodworking but enhances it. By taking over repetitive and labor-intensive tasks, these technologies allow artisans to focus on intricate details and unique touches that showcase their individual style and creativity. The marriage of traditional techniques with modern technology creates a dialogue; artisans can innovate while remaining true to their craft’s roots. For example, CNC machines can produce components that require a level of accuracy that manual crafting alone could not achieve, yet the final assembly and finishing can still reflect the artisan’s skill and personality.

Furthermore, technology assists in the preservation and sharing of craftsmanship knowledge. Digital catalogs and online platforms allow woodworkers to document their processes and techniques, creating a repository of skills that can be shared within the community. This exchange of information fosters growth and inspires future generations of woodworkers, ensuring that the craftsmanship is not only sustained but also evolved. The influence of technology is transforming woodworking into a collaborative space where ideas are exchanged freely, enriching the craft with diverse perspectives and experiences.

Future Trends in Woodworking Shops

The future of woodworking shops is poised for even greater transformation as the continuous evolution of technology brings innovative solutions that enhance efficiency, creativity, and sustainability. The rise of woodworking business software in the UK is already setting the stage for a new era of operational excellence within these establishments. As these tools become increasingly sophisticated, they will allow for enhanced data analytics and predictive modeling, giving shop owners the ability to forecast trends and adjust their production strategies accordingly. This forward-thinking approach will lead to more responsive operations that can quickly adapt to changing consumer demands and market conditions.

In addition, the integration of artificial intelligence and machine learning capabilities within woodworking business software will enable shops to refine their processes further. Imagine software that learns from past orders and customer feedback to optimize inventory management, predict supply chain issues, or suggest material substitutions that align with customer preferences and sustainability goals. This technological advancement could significantly reduce waste, making the woodworking industry greener and more resource-efficient, which is crucial as consumers increasingly seek eco-friendly products.

Moreover, the advancement of augmented reality (AR) and virtual reality (VR) within woodworking is on the horizon. These technologies could allow customers to visualize their custom pieces in their space before production begins. This interactive experience offers enhanced customer engagement and satisfaction, as clients can make adjustments to their design with immediate visual feedback. Furthermore, AR can assist woodworkers themselves by overlaying digital information onto physical components, aiding in measuring and assembly, leading to more precise outcomes.

As woodworking shops continue to embrace technology, they are also likely to become more interconnected through the Internet of Things (IoT). Smart machines equipped with sensors will relay real-time performance data, allowing shop owners to monitor equipment health and predict maintenance needs. This proactive approach will minimize downtime and keep production running smoothly. The synergy between smart tools and human craftsmanship will enhance not only operational efficiency but also foster a collaborative atmosphere where innovation thrives.

Lastly, education and training in the woodworking field will adapt as technology advances. With the proliferation of virtual training platforms and interactive learning tools, aspiring woodworkers will have access to a wealth of resources that highlight both traditional techniques and modern technology. This accessible knowledge will empower the next generation to blend time-honored craftsmanship with cutting-edge innovations, ensuring the art of woodworking continues to evolve and flourish in an increasingly digital world.